Back to About my research

Back to About my research

ARTHETA-0: An Innovative, Affordable Approach to the Onsite, Rapid 3D Printing of Artery Stents, Parameterized to Fit Individual Patients' Needs

Website: artheta.us

Prabuddha Ghosh Dastidar & Connor Mitchell

North Carolina School of Science and Mathematics, Durham, NC, US

Honors and Awards

2021 Regeneron International Science and Engineering Fair 2nd Place Grand Award (Biomedical Engineering)

2021 Regeneron International Science and Engineering Fair Sigma Xi 2nd Place Award (Physical Science)

2021 Biomedical Engineering Society High School Poster Exposition 1st Place Award

Selected to Deliver Industry Webinar for Biomedical Engineering Society

Featured in Charlotte Observer Newspaper (Front Page and Continued on Page 10A)

Conrad Spirit of Innovation Challenge Innovator (Health & Nutrition)

Technological Student Association State Medalist (Biotechnology Design)

North Carolina Student Academy of Sciences State Medalist (Advanced Engineering)

North Carolina Science and Engineering Fair Region 3B Overall Grand Award Winner

Abstract: The stent manufacturing industry, as it stands, uses extremely inefficient and unaffordable methods, such as laser-cutting, to fabricate stents. These methods require extensive infrastructure and must therefore be completed at an external location. Additionally, these methods follow a one-size fits all approach when manufacturing stents. The ARTHETA-0 is a 3D printer with a novel motion system that specializes in printing vascular-stents. It addresses all of the shortcomings of the stent manufacturing industry. It uses a novel, simplistic motion system that utilizes polar coordinates and a horizontally-static print bed to print stents made of Thermoplastic Polyurethane (TPU). This allows the ARTHETA-0 to be incredibly affordable at under $500 (versus industry standards which exceed $100,000), while still printing stents with incredible accuracy and precision (due to its innovative motion system that can print cylindrical structures with almost no ovality). The simplistic fused deposition modeling (FDM) system makes the ARTHETA-0 extremely accessible. It can be implemented on-site, in hospitals and can print stents that are customized to patient-specific dimensions, unlike anything seen before. Stents can be printed within two hours of parameter input, eliminating shipping times. Additionally, the actual stents are of high quality and are of complex designs due to the dual extrusion system in the ARTHETA-0, which uses Polyvinyl Alcohol (PVA) as a support material to print the stent with TPU. Once placed in water, only the PVA dissolves. The stents are also biodegradable due to the usage of TPU, reducing the risk of post-stenting complications such as restenosis.

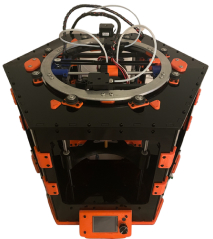

Figure 1: Image of the prototype unit of the ARTHETA-0. Approximate footprint of the printer is 3 cubic feet

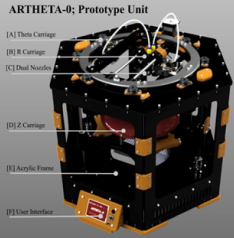

Figure 2: ARTHETA-0 prototype unit diagram. A. Theta Carriage. B. R Carriage. C. Dual Nozzles. D. Z Carriage. E. Acrylic Frame. F. User Interface.

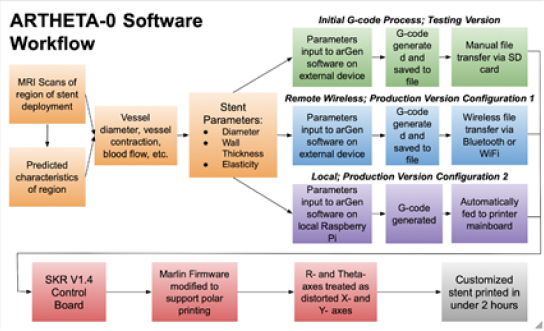

Figure 3: Upper level software workflow for ARTHETA-0. Based off measurements of stent deployment region from MRI scans, as well as predicted characteristics of the region, stent parameters are input into the arGen software, which generates the g-code necessary to print the specified stent. The g-code is then transferred to the printer control board in one of three ways, determined by the printer model and configuration, where it is processed by modified Marlin Firmware to execute the printing procedure.

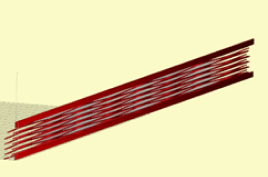

Figure 4: Visualization of arGen g-code output generated by Pronterface, a 3d printing control software, which renders g-code in a cartesian form. This causes the linear display shown above, even though the g-code is processed and printed in a polar manner.

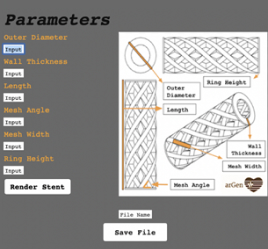

Figure 5: Visualization of the beta version of the arGen Graphical User Interface (GUI) Application. Users can input stent parameters, render the stent to observe a visualization, and export the file to a specified address.

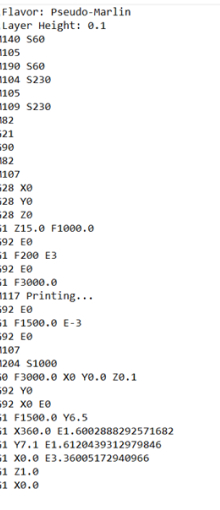

Figure 6: A sample of g-code generated by the arGen software for stent fabrication. The average g-code file for stents of similar specifications is approximately 5000 lines, where each line consists of a separate printer command.